How to Remove a Screw Without a Screwdriver (Household Hacks That Work in a Pinch)

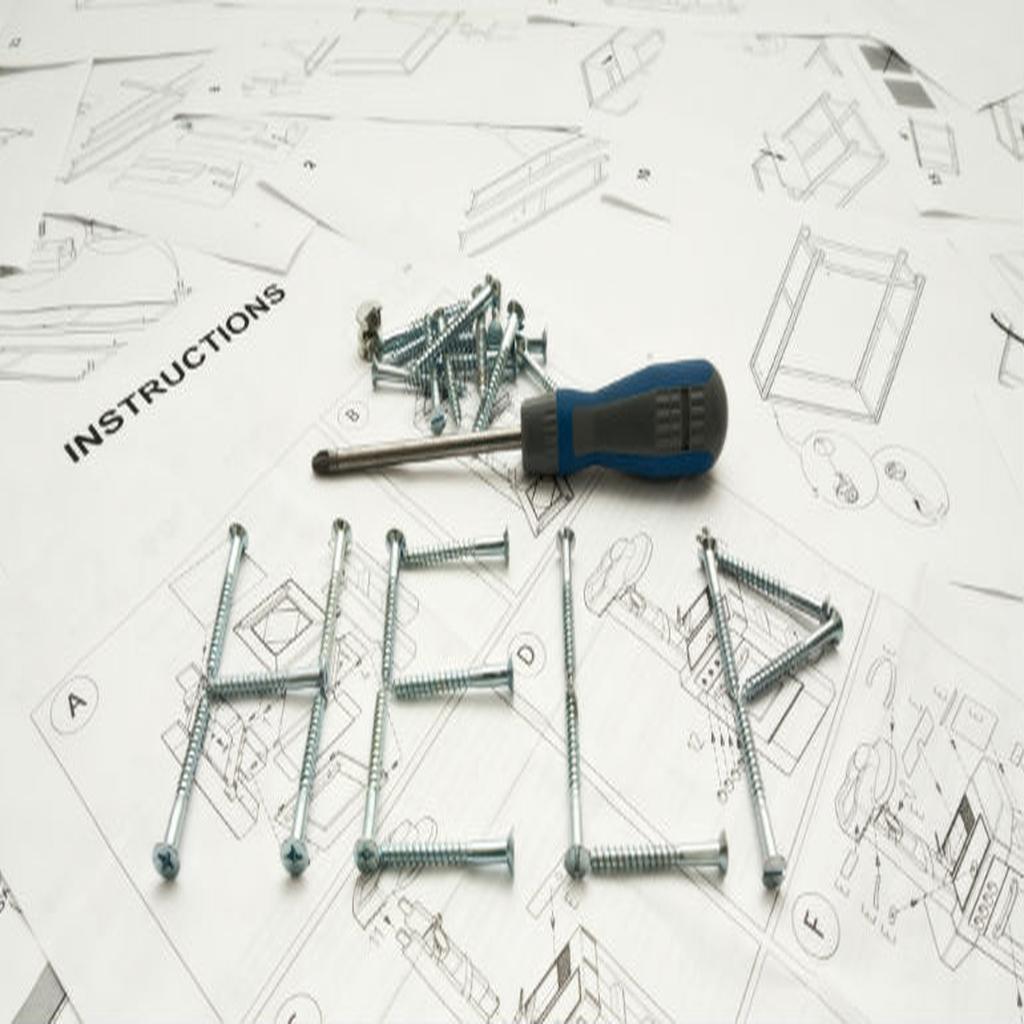

Ever gone to disassemble a bit of flat‑pack furniture, pop open a laptop case, or take down a wall bracket—only to realise you can’t find a screwdriver anywhere? You’re not alone. Even seasoned tradespeople occasionally get caught without the right driver bit or a screwdriver. The good news: you probably have several everyday household items that can stand in—carefully—for a screwdriver long enough to get the job done.

Safety First! These workarounds are temporary fixes. Whenever possible, use a screwdriver to reduce the risk of injury, material damage, or stripping the screw head. Wear eye protection when prying, sawing, or melting plastic. Work slowly and stop if the tool slips.

Table of Contents

- Know Your Screw: Phillips vs. Flathead vs. Small Screws

- Quick Safety & Success Tips

- Emergency Tools for Phillips Head Screws

- Use a Flathead screwdriver

- Use a Coin

- Use a Butter Knife

- Cut a Deeper Slot With a Hacksaw

- Melt & Mold an Old Toothbrush

- Use an Old CD (Loose Screws Only)

- Grip With Pliers

- Use Your Thumbnail (Very Loose Screws)

- How to Remove a Flathead Screw Without a Screwdriver

- Coin

- Butter Knife

- Pliers

- Thumbnail

- Plastic Card

- Can Tab

- Removing Small Screws (Electronics, Eyewear, Gadgets)

- Knife Tip

- Metal Nail File

- Small Scissors

- Tweezers

- Troubleshooting: Stripped, Stuck, or Damaged Screws

- When to Stop & Get the Right Tool

- Wrap‑Up

Know Your Screw: Phillips vs. Flathead vs. Small Screws

Before you improvise and use a temporary screwdriver, identify what you’re dealing with:

Phillips head screws have a cross‑shaped recess (two intersecting grooves). They’re everywhere—from furniture to appliances. Because the recess corners are narrow, they strip easily if you use the wrong tool or too much force.

Flathead (slotted) screws have a single straight groove across the head. They’re common in older furniture, electrical plates, and some hardware.

Small / precision screws show up in electronics (laptops, phones, eyewear, battery compartments). Their heads are tiny and delicate—easy to damage, so work gently.

Lefty loosey, righty tighty: Turn counter‑clockwise to remove (unless you’re dealing with specialty reverse‑thread hardware—rare in household items).

Quick Safety & Success Tips

- Match the fit. Whatever substitute you use should fill the groove as fully as possible. Gaps = slippage.

- Downward pressure matters. Press firmly into the screw while turning so the tool doesn’t cam out (jump out of the groove).

- Start gently. Try short, controlled turns. Rock the tool slightly to seat it deeper.

- Penetrating oil helps. A tiny drop (WD‑40, light machine oil, even cooking oil in a pinch) can loosen stubborn screws.

- Protect surfaces. Masking tape around the screw head prevents accidental gouges in wood, paint, or plastic.

- Know when to stop. If the head starts to deform, switch tactics before you fully strip it.

Emergency Tools for Phillips Head Screws

Phillips heads are easy to damage, so pick the method that gives you the most stable engagement. Work slowly.

Use a Flathead Screwdriver

If you own any driver at all, odds are it’s a flathead. Seat the blade in the longer of the two Phillips grooves and turn counter‑clockwise. Use a blade just wide enough to bite both opposing corners; too small and you’ll round the recess.

Use a Coin

A small, thin coin (pennies often work) can turn larger Phillips screws. Insert the coin edge into the deepest groove and twist. Works best when the screw isn’t overly tight.

Use a Butter Knife

Hold the knife vertically and insert the blade tip into one groove. Apply steady, even torque. If the screw is tight or the knife is flimsy, the blade may bend—so choose a sturdy utensil.

Cut a Deeper Slot With a Hacksaw

When the screw head sits proud (above the surface) and you can’t get a good bite, carefully extend one groove with a hacksaw blade to create a deeper slot. After cutting, switch to a flathead driver or coin for removal. Wear eye protection and protect the surrounding surface before sawing.

Melt & Mold an Old Toothbrush (Last Resort)

Heat the end of a disposable toothbrush (lighter, candle, or heat gun—carefully). When the plastic softens, press it into the Phillips recess and hold until cool. Once hardened, twist the handle to turn the screw. Best for loose screws only—tight screws will snap the plastic and could leave melted residue in the head.

Use an Old CD (Loose Screws Only)

Slip the edge of an unwanted CD into one groove and turn gently. If the disc starts to flex or warp, stop immediately—the screw is too tight and the disc could shatter.

Grip With Pliers

If the head stands above the surface, lock a pair of pliers around it and twist counter‑clockwise. Needle‑nose pliers can sometimes grip the cross recess walls if the head is shallow; locking pliers (Vise‑Grip style) give better leverage.

Use Your Thumbnail (Only if Very Loose)

Press your nail edge into one groove and twist. Stop at the first sign of pain or slippage. This is strictly for screws that are already mostly out.

How to Remove a Flathead Screw Without a Screwdriver

Flathead (slotted) screws are often easier to improvise with because anything thin and flat that fits the slot can work. Many Phillips tricks apply here too.

Coin

Slide the thin edge of a coin into the slot. Works great on larger screws like those in furniture and electrical plates.

Butter Knife

Use either the flat tip or the side of the blade, whichever fills the slot better. Keep downward pressure to avoid slipping and scratching the surrounding surface.

Pliers

If the screw head sticks out, grab it firmly and twist. Rock the pliers back and forth to gradually loosen a stuck screw.

Thumbnail

For very loose screws, your nail may be enough to finish the job once the screw is partially backed out.

Plastic Card (Credit / Library / Loyalty Card)

Use only a card you can afford to damage—snapping is common. Wedge a corner or edge into the slot and twist. This gives surprising leverage on shallow, low‑torque screws.

Can Tab

Remove the pull tab from an aluminium drink can. The flat inner edge can catch a slot in a pinch. Use slow, gentle turns; aluminium bends easily.

Removing Small Screws (Electronics, Eyewear, Gadgets)

Tiny screws are notoriously awkward—even with proper drivers—because the heads strip with very little torque. Cushion your work surface, use good lighting, and consider magnification.

Knife Tip

Insert the point of a small, sharp knife (craft knife, pocket knife) into the recess. Angle slightly so the edge bites. Turn gently; too much force will cam out and damage the screw or slip into nearby components.

Metal Nail File

The tapered tip on many metal files fits miniature slots. Seat it firmly and turn slowly. Don’t over‑torque; the file can skid and mar delicate surfaces.

Small Scissors

Precision vanity or embroidery scissors often have thin, pointed blades. Fit one blade tip into the screw head and twist. Sharp blades work best; dull ones will skate.

Tweezers

If your tweezers have sharply pointed ends, place one tip in the recess and rotate. Some tweezers can also grip the outside of a proud screw head. Broad‑tip cosmetic tweezers usually won’t fit.

Troubleshooting: Stripped, Stuck, or Damaged Screws

Stripped Phillips head: Try seating a wide rubber band over the head, then push your improvised driver through the rubber to gain friction. (Works best before the head is fully stripped.)

Slot filled with paint or debris: Clean with a utility blade, pin, or the tip of a paperclip before attempting removal.

Rusty screws: Apply penetrating oil and let sit 5–10 minutes. Tap the head lightly with a hammer handle to break corrosion.

Head snapped off: If some shank protrudes, grip with locking pliers. Otherwise you may need a screw extractor or to drill it out—time to get proper tools.

When to Stop & Get the Right Tool

Improvisation is fine for:

- Lightly snug household screws.

- Decorative hardware you’re already replacing.

- Quick, one‑off fixes when the correct tool is temporarily unavailable.

Buy or borrow proper tools if:

- The screw is load‑bearing (shelves, wall mounts, child safety fixtures).

- You’re working inside electronics you care about.

- The head is starting to deform.

- You need to remove many screws.

A small multi‑bit driver kit plus a precision electronics set will cover almost every household need and save you time and frustration down the road.

Wrap‑Up

You don’t always need a perfect screwdriver to loosen a stubborn fastener. With a bit of creativity—and caution—you can press everyday items into service: coins, butter knives, pliers, toothbrushes, cards, even can tabs. Just remember: fit matters, pressure matters, and knowing when to stop matters even more.

Check out SAVERSTREET HAND TOOLS for great deals.